What is an Environmental Test Chamber Used For?

Environmental test chambers are designed to maintain user-specified atmospheric conditions, through temperature, humidity, airflow, and light cycling controls, for stability and shelf-life testing of pharmaceuticals, cosmetics, raw materials or food products.

Test Chamber Guidelines and Standards

The guidelines for product stability testing are published by the International Council for Harmonization of Technical Requirements for Pharmaceuticals for Human Use, or ICH. The ICH’s guidelines define acceptable temperature and humidity ranges, deviations from setpoints, length of testing intervals, and uniformity across the internal chamber.

Stability Test Chamber Construction Material

Depending upon the intended use of the product, stability testing durations may range from several days to one year. As such, environmental test chambers are built with durable painted-steel exteriors and aseptic, rigid stainless steel interiors to handle the rigors of long-term testing.

Testing Chamber Airflow

To ensure optimal uniformity across the testing area, environmental testing chambers are designed with horizontal laminar airflow systems that include a positive-pressure feed plenum on one side of the chamber and a negative-pressure return plenum on the opposite side.

Read More: Environmental Test Chambers 101

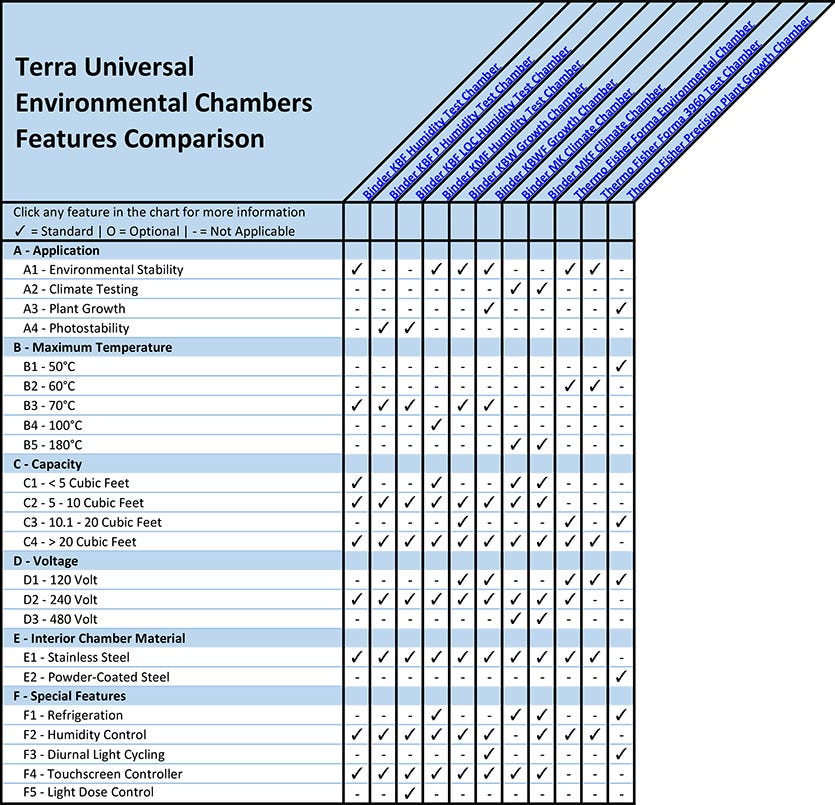

A - Environmental Test Chamber Application

(back to chart)

Environmental test chambers are designed for four primary applications: humidity chambers, climate test chambers, photostability chambers, and growth chambers. Humidity chambers are designed to control temperatures from ambient to, most commonly, 70°C and humidity levels from 10% to 98% RH.

Humidity test chambers include cooling coils to reduce the internal temperature down to refrigerated levels (4°C). Climate test chambers offer a broader temperature range than humidity test chambers, normally -40°C to 180°C, to simulate extreme environmental conditions.

Photostability chambers include UV and fluorescent lights to expose pharmaceutical or cosmetic samples to differing lumen dosages.

Plant Growth chambers control temperature and humidity to simulate optimal growth conditions for plant organisms, like Arabidopsis, or seed germination studies.

B - Maximum Test Chamber Temperature

(back to chart)

Standard environmental test chambers maintain temperatures from ambient to 70°C, though certain models utilize cooling coils to reduce temperatures down to 4°C.

Growth chambers are designed to simulate optimal germination conditions for seeds and plant organisms and, thus, cannot maintain temperatures above 50°C.

Climate testing chambers offer the broadest temperature range in the industry, commonly -40°C to 180°C.

C - Environmental Test Chamber Size and Capacity

(back to chart)

Environmental test chambers are manufactured to a standard range of sizes based on sample storage capacity.

Compact, low-throughput models provide 2 cubic feet or 4 cubic feet of storage space, whereas high-throughput, free-standing units provide up to 29 cubic feet of storage space.

Standard test chambers include adjustable shelves installed on steel racks to maximize sample storage capacity within the internal chamber.

Given the side-mounted plenums external to the inside chamber space, the working footprint of the test chamber is significantly larger than the storage capacity.

D - Environmental Test Chamber Voltage

(back to chart)

120-volt connections are suitable for standard laboratory power outlets in the United States.

240-volt connections, common in Mainland Europe, require less current (amperage) and smaller conductors than equipment designed to operate at 120-volt.

Specialty high-voltage equipment requires 480-volt connections and carries additional protection against electrical hazards.

E - Environmental Chamber Interior Material

(back to chart)

Stainless steel is compatible with alcohol-based cleaners, resists corrosion, and promotes aseptic conditions. Powder-coated steel represents an economical alternative to stainless steel but may chip after prolonged exposure to bleach-based disinfectants.

F - Special Environmental Test Chamber Features

(back to chart)

F1 - Refrigerated Environmental Test Chambers ion

Refrigerated test chambers maintain temperatures down to 4°C for shelf-life testing or stability testing of pharmaceuticals. Refrigerated models can also serve as short-term storage spaces for temperature-sensitive food products and raw materials.

F2 - Humidity Control Test Chambers

Humidity test chambers maintain RH levels from 10% to 98% per ICH guidelines. Visual and audible alarms activate if temperature or humidity conditions fall outside of the standard range.

F3 - Diurnal Light Cycling Chambers for Plants

Plant growth chambers contain fluorescent lighting for programmed daily light and dark (or day/night) cycles defined over a one-week period.

F4 - Touchscreen Environmental Controller

Ergonomic touchscreen controllers include time segmenting, real-time programming, data logging and export, system diagnostic testing, and audible/visual alarms.

F5 - Light Dose Control for Testing Chambers

Certain photostability chambers include light dosage control for UV-A and fluorescent, visible light per ICH guidelines.

Where Can I Buy Environmental Test Chambers Online?

Laboratory-Equipment.com is a specialty division of Terra Universal. For nearly 40 years, Terra Universal has served semiconductor, aerospace, life science, pharmaceutical, biotechnology, and medical device markets. Customers appreciate a worldwide network of reps, factory-direct support, and ready-to-ship items available from Terra's manufacturing and warehouse facilities in Fullerton, California.

Shop Test Chambers Online to compare pricing, features, and selection for a wide variety of lab equipment including test chambers, dispersers, shakers, stirrers, and cold storage. Browse lab equipment for applications including general laboratory, plant growth, genetic research, novel strain development, PCR, DNA/RNA techniques, ELISA, protein analysis, and cell culture.